Neutrasystem 2™ pH Monitoring System

Neutrasystem 2™ monitors discharge from Neutratank® neutralization tanks to ensure they are within acceptable pH levels.

product overview

The system continuously samples the downstream flow while keeping an accurate, permanent record of pH discharge levels. The pH monitoring device will warn maintenance personnel (visually and audibly) when pH discharges outside acceptable parameters are sensed.

Neutrasystem 2™ offers pH monitoring and recording with continuous sampling of downstream flow. It is commonly used in applications such as:

- Industrial plants

- University Laboratories

- Schools

- Hospitals

- Pharmaceuticals facilities

- Chemical manufacturing

features & benefits

- Equipped with submersible, chemical-resistant CPVC pH electrode (sensor) with automatic temperature compensation

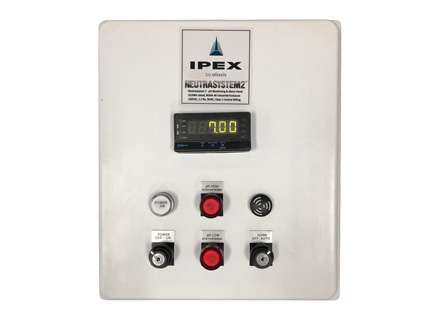

- Durable UL 508 Listed, NEMA 4X monitoring panel

- Tough 5-gallon high-density polyethylene sample tank

- Intermittent alarm horn, (sonalert type), and alarm silencing switch. The alarm horn is activated when the probe senses a pH above or below the set parameters and will remain on until the alarm silencing switch is activated

- Large 4-digit pH value display with operator buttons for alarm settings (High pH value, Low pH value to energize the alarm)

- Ethernet output for pH level and alarm in current time (optional)

- Data logger to record pH values with date and time (optional)

specifications

The specification section covers the details you need for your project.

- Key lock off-on switch on the door

- Control power has a 2 amp fuse with a blown fuse indicator (24VDC class 2)

- pH Monitoring and Recording System for Neutratank® HDPE and polypropylene neutralization tanks

Specifications

Other Specifications of the product:

- UL 508 Listed monitoring and control panel

- NEMA 4X rated enclosure

- “Power ON” white LED pilot light

- “pH HIGH Alarm” LED red light/ button to press to acknowledge

- “pH LOW Alarm” LED red light/ button to press to acknowledge

- Series 6510 submersible, pH electrode with chemically resistant CPVC body, viton O-rings, and twist-lock connection providing easy maintenance

The acid waste monitoring system shall be the Neutrasystem 2™ pH Monitoring System as supplied by IPEX Industrial Systems, comprising of a UL 508-listed, NEMA 4X, electrical pH monitoring panel and a 5-gallon high-density polyethylene, one-piece construction, rotationally molded sampling tank. The control panel shall incorporate a sonalert soft internal alarm horn with a silencing switch, pH HIGH and LOW LED red light alarms, and power ON white LED pilot light. The controller shall link, via preamplifier, to a Series 6510 submersible pH electrode encapsulated in a chemically resistant CPVC body with Viton O-rings.

The electrode shall have a flat sensing surface and the electrode body shall incorporate a twist lock connection to facilitate easy removal and replacement. The electrode shall have a response time of 5-10 seconds for pH changes. The 5-gallon pH sampling tank shall be installed downstream of a rotationally molded construction, high-density polyethylene Neutratank® with a flanged top, and a combination bolt down and access cover. Connecting piping for the acid waste drainage and vent system shall be NSF- listed Schedule 40 polypropylene conforming to ASTM F1412 as manufactured by IPEX.

Connecting fittings shall be NSF-listed, incorporating molded-in-place nickel chrome wire and joined using the Enfield Hand Held Control Unit, or all-plastic construction mechanical joint fittings incorporating anti-pull-out collars (olives) to insure against accidental pipe-fitting separation during and after installation. Installation and testing of the Neutrasystem 2™ shall be in accordance with the contract drawings, the manufacturer’s recommendations, and the local plumbing codes.