System 636® Flue Gas Venting

A Complete System of Fully Certified Pipes, Fittings and Cements

Only IPEX offers System 636® Flue Gas Venting, a complete system of pipe fittings, termination kits and cements engineered and manufactured to strict quality, performance and dimensional standards.

System 636® PVC and CPVC pipe are made to sturdy Schedule 40 dimensions providing strong, rigid pipe for use in demanding applications. A full range of vent fittings and accessory components are also offered to complete the system.

Venting Solutions for Condensing Appliances

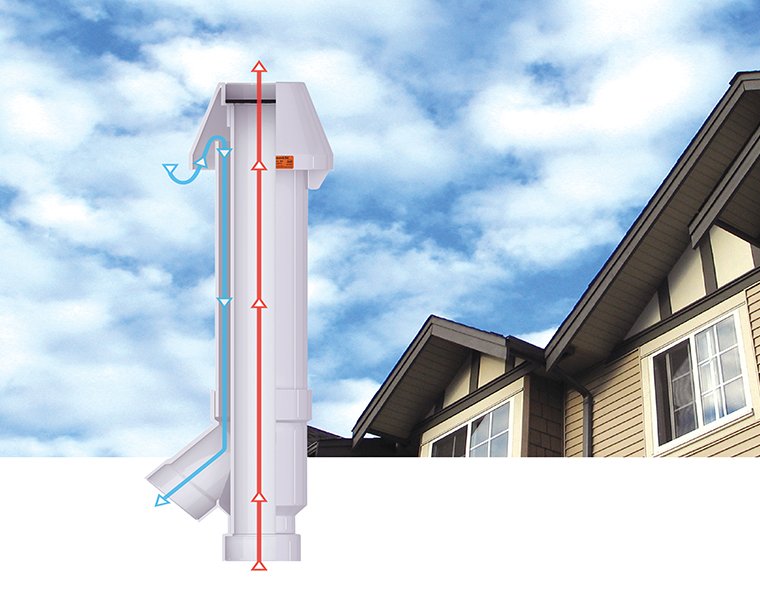

Gas-fired condensing appliances such as furnaces or hot water heaters normally require two vent pipes, one for the fresh air and one for the exhaust, typically referred to as direct venting. A power vented gas-fired appliance only requires one pipe for the exhaust while the appliance draws in room air.

Offering multiple termination options such as the low-profile termination kit, CVK, and UCVK, provides flexibility to suit various installation needs and aesthetic preferences.

Common Venting Solution

Common venting allows multiple gas-fired appliances of the same brand and model to share a dedicated vent pipe for fresh air intake and exhaust. In 2015, the CSA B149.1 Natural Gas and Propane Installation Code, was updated to allow common venting if all appliances are of the same type and manufacturer, certified for common vent configurations, and equipped with a flue backflow prevention valve.

IPEX Specialty Fittings for Common Venting

Engineered Backflow Valve: The first PVC and CPVC valve with an integrated in-line condensate drain, requiring no priming.

Cleanout Condensate Drain: Integrated with a ball check valve that self-drains without priming.

Common venting reduces the number of vents in and out of a building, saving installation time, space, and costs while preserving the structural integrity and aesthetics. It’s ideal for residential, commercial, institutional, and industrial applications with high hot water demand.

Fully Certified Solutions

System 636® is offered in two distinct materials, PVC & CPVC, each with a unique temperature rating. These venting systems are approved as Type BH vents and are designed for negative or positive pressure venting of gas-fired appliances. They comply with CSA B149.1, requiring ULC S636 certification across Canada.

PVC (Polyvinyl Chloride)

System 636® PVC carries a ULC S636 Class IIA certification and is certified for use up to and including 65°C (149ºF). Ensure the proper System 636® PVC Cement and Primer is to be used for installation.

CPVC (Chlorinated Polyvinyl Chloride)

System 636® CPVC carries a ULC S636 Class IIB certification and is certified for use up to and including 90°C (194ºF). Ensure the proper System 636® CPVC Cement and Primer is to be used for installation.

- IPEX recommends that installers receive formal training on System 636® every 3 years to ensure proper installation methods are used at all times.

TOP RESOURCES

Learn More About System 636® Flue Gas Venting Systems

Our resources section covers everything you need to know about System 636® Flue Gas Venting System.

IPEX offers on-going installer training and a comprehensive installation guide. The guide forms part of the certification process and contains critical information on the installation, ensuring successful, code compliant completed projects.

Take a look at our most popular resources below:

Specifications

SYSTEM DESCRIPTION

System 636® Flue Gas Venting is fully certified as a complete pipe, fittings, and cement system. The system is available in a PVC and a CPVC version.

The venting systems are approved as Type BH vents and designed for negative or positive pressure venting of gas-fired appliances.

Material

PVC

Maximum Flue Gas Temperature

65°C (149°F)

Pipe Size Ranges

1-1/2 – 6″ (38 – 150 mm)

Standards and Certifications

ULC S636

Applications

Non-combustible buildings, as detailed in clause 3.15.16 of the National Building Code (NBC)

Material

CPVC

Maximum Flue Gas Temperature

90°C (194°F)

Pipe Size Ranges

1-1/2 – 8″ (38 – 200 mm)

Standards and Certifications

ULC S636

ULC S102.2 Flame Spread Rating 10

ULC S102.2 Smoke Developed Classification 50

Applications

Non-combustible buildings, per National Building Code (NBC) classification

Air plenums (per NBC classification)

Buildings deemed to be high buildings (by NBC classification)