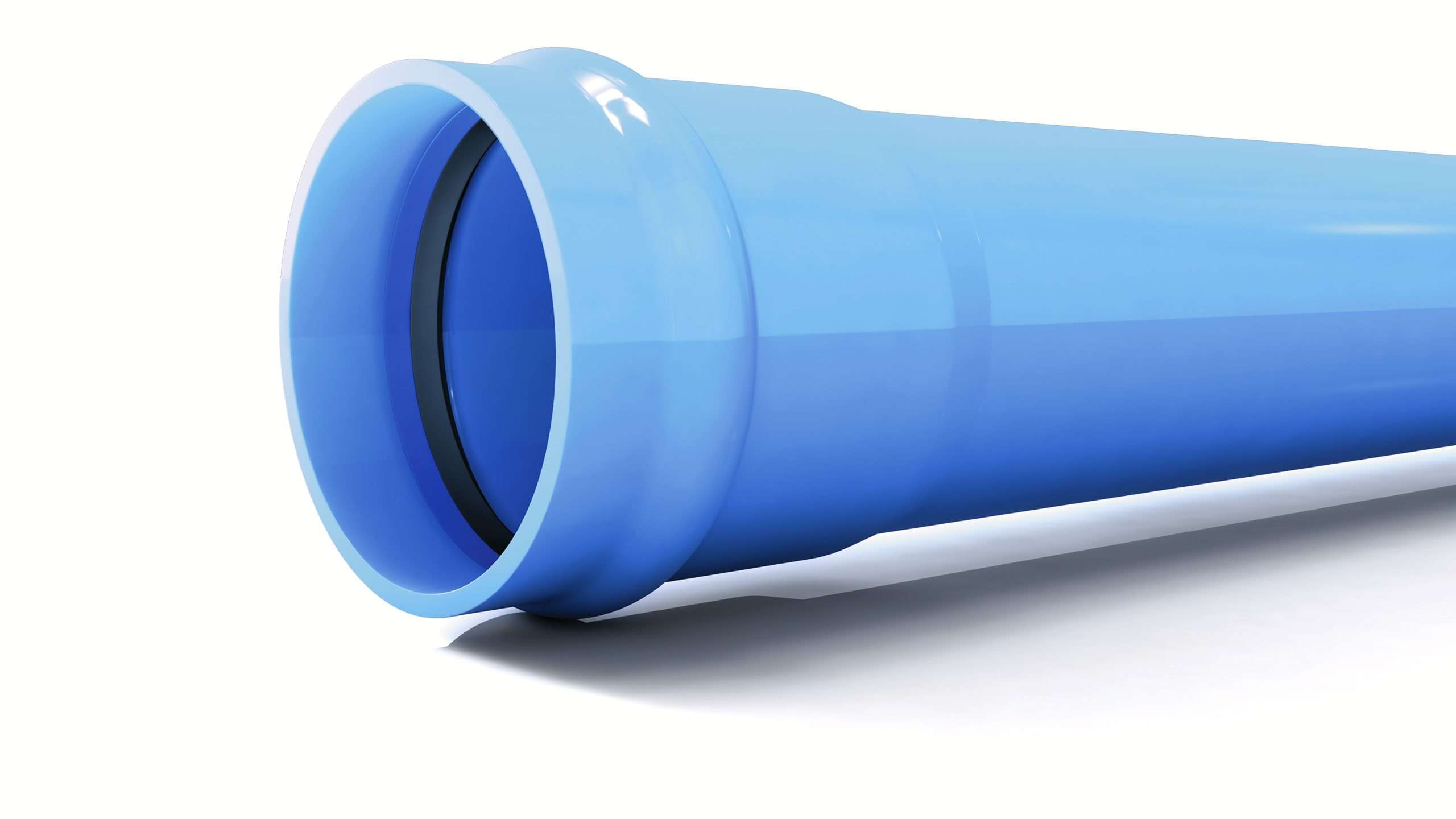

Bionax® SR combines the same strength, toughness and flexibility as standard Bionax pipe with the enhanced seismic-resistance benefits of an extended bell.

The result is a municipal water transmission and distribution system which performs better than any pipe product available today. Bionax® SR can improve absorption of the lateral ground strain of seismic events and provides other performance benefits including product consistency, industry standard dimensions, and corrosion-resistant attributes for North American jobsites.

product details

Bionax® SR features

- Compatible with North American pipes and fittings (CIOD)

- Exceeds the Japanese seismic design standard by 70%

- Corrosion resistance

resources

Learn more about our Bionax® SR Seismic Water Pipe

Product Details

This specification provides the requirements for Bionax SR molecularly oriented polyvinyl chloride (PVCO) pipe for potable-water systems and other pressure-pipe applications. Bionax SR Gasketed cast-iron-pipe outside diameter (CIOD) Pressure pipe is available in the following pressure classes and nominal sizes:

PC 235psi 6″ through 12″ (150mm – 300mm)

Material

Bionax SR pipe shall be manufactured from rigid polyvinyl chloride (PVC) compound meeting the requirements of ASTM D1784 cell class 12454. Bionax SR gaskets shall meet ASTM F477 for high-head applications.

Hydrostatic Design Basis

Starting-stock for Bionax SR shall have a hydrostatic design basis (HDB) of 4000 psi and finished pipe shall have an HDB of 7100 psi as determined by testing in accordance with ASTM D1598, with data evaluated in accordance with ASTM D2837.

Pipe

Bionax SR shall be manufactured with cast-iron-pipe outside diameters (CIOD) in all sizes. Pipe walls shall meet minimum thickness requirements for AWWA C909 and CSA B137.3.1. Laying lengths shall be 6.1 meters (20 feet). Pipe shall be joined by means of integral-bell elastomeric-gasket joints conforming to ASTM D3139. Spigot ends shall be chamfered by the manufacturer. Pipe ends shall be capped at the production facility prior to storage and shipping.

Standards

PVCO pipe shall conform to the following standards:

ASTM F1483 Standard Specification for Oriented Poly(Vinylchloride), PVCO, Pressure Pipe (PR 200psi)

ANSI/NSF Standard 61: Drinking Water System Components – Health Effects

ANSI/NSF 14 Plastics Piping System Components and Related Materials

AWWA C909: Molecularly Oriented Polyvinyl Chloride (PVCO) Pressure Pipe, 4 inch through 24 inch (100 mm through 600 mm) for Water Distribution

BNQ NQ 3660-950 Safety of Products and Materials in Contact with Drinking Water

CSA B137.3.1 Molecularly Oriented Polyvinylchloride (PVCO) Pipe for Pressure Applications

FM 1612 Polyvinyl Chloride (PVC) Pipe and Fittings for Underground Fire Protection Services

Bionax SR piping systems shall include IPEX Blue Brute molded and fabricated fittings.

Lubricant

Pipe must be assembled with IPEX water-soluble lubricant listed to NSF Standard 61.

Color Coding

CIOD pipe shall be color coded blue.

Specifications

PVCO

6″ – 12″ (150mm – 300mm)

235 psi (CSA/AWWA)