Scepter® Rigid PVC Fittings

IPEX Inc.

Scepter® Rigid PVC conduit fittings off a wide range of boxes, fittings, couplings and elbows.

Scepter offers a comprehensive offering of PVC nonmetallic conduit fittings including adapters, couplings, elbows, access fittings, boxes, cover plates and expansion fittings virtually any fitting required to complete the PVC conduit system.

Easy installations, the ability to perform in demanding environments and labor savings are the reasons nonmetallic conduit fittings chosen by contractors. Scepter PVC conduit fittings offer both high impact and tensile strength, are nonconductive and are resistant to a wide range of chemicals such as acids, alkalis and salt solutions.

Product Details

Available in 1/2″ – 8″ (12mm – 200mm) sizes

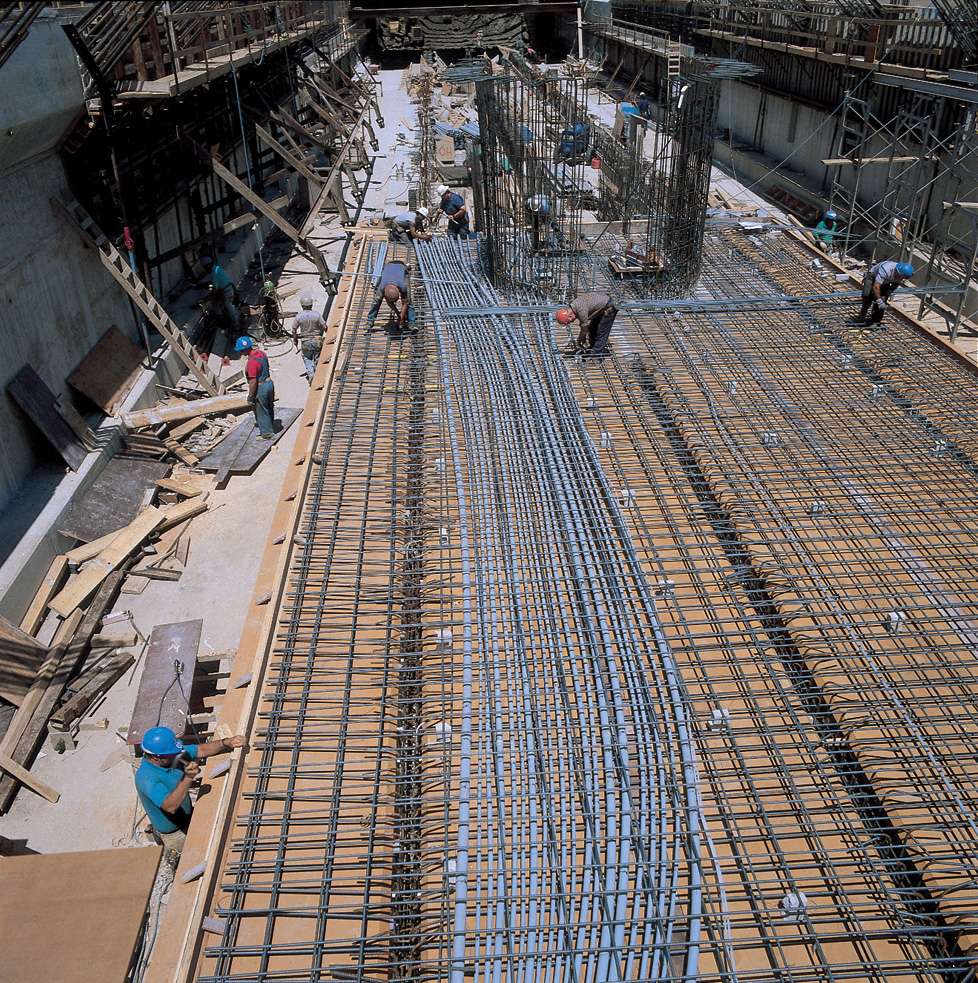

Scepter rigid PVC fittings can be used in nearly any application from Utilities, Airports, Parking garages to water and sewer treatment plants.

Suitable for exposed, concrete encased and direct burial, IPEX PVC fittings are concrete tight in all weather conditions and offer high impact and tensile strength.

Advantages

Advantages of Scepter Conduit

- Fire resistant: IPEX’s proprietary PVC compound used to manufacture Scepter products is a self-extinguishing material and will not support combustion. Samples taken from an actual fire show the outer surface of the conduit was blistered and charred. The interior of the conduit, however, was unaffected. Additionally, the undamaged conductors were then removed and reinstalled in new conduit. Fire-resistant characteristics when tested to CAN ULC S102.2.

- Nonconducting: Scepter Rigid PVC Conduit pipe and fittings are nonsparking and nonconducting, thereby eliminating the most dangerous ‘second point of contact’ and ‘phase to ground’ faults. The use of a separate grounding conductor in a Scepter PVC conduit system gives a complete and positive ground for the whole system.

resources

Discover more about IPEX

Our resources section covers everything you need to know: Take a look at our most popular resources below

Product Details

All wiring shall be installed in Rigid PVC conduit and secured to PVC boxes and cabinets by means of proper fittings. All boxes, access fittings and covers shall be furnished with threaded brass inserts, brass screws and PVC gaskets. Rigid PVC fittings and junction boxes shall be used for all outlets, pull boxes and junction points. All PVC junction boxes shall be NEMA 1, 2, 3, 4, 4X, 6P, 12 and 13 rated and UL Listed for wet locations.

Exposed conduit shall be securely held in place by suitable hangers or straps with the maximum spacing of points for supports not exceeding those specified in the CEC or NEC. Except when embedded in concrete, rigid conduit pipe shall not be clamped tightly. It shall be supported in such a manner as to permit adequate linear movement, allowing for expansion and contraction of conduit due to temperature change. Where a temperature change exceeding 25°F (14°C) is anticipated, rigid PVC expansion joints shall be installed in accordance with the manufacturer’s recommendations.

Proper care shall be taken when field bending, to maintain the internal diameter and wall thickness of the conduit. The contractor shall furnish and install Scepter Rigid PVC conduit pipe and fittings made by IPEX. Where the engineer’s specifications indicate Scepter products or equivalent, the equivalent shall be CSA certified and accepted by the Canadian Electrical Code. Due to broad manufacturing tolerances, all pipe and fitting products shall be of the same manufacturer.

Specifications

PVC

1/2″ – 8″ (12 – 200 mm)

C22.2 No. 211.2, CSA C22.2 No. 211.0

NSF Certified to UL651

Sunlight Resistant

Rated for use with 90°C conductors

NEMA TC2

Corps. of Engineers Spec. CE 303:01

Military Spec, Federal Spec. WC 1094A

Utilities

Parking Garages

Cable

Car Washes

Communications

Fish Plants

Residential

Mines

Airports

Marinas

Subways

Steel Mills

Bridges and Tunnels

Water Treatment Plants

Sewage Treatment Plants

Pulp and Paper Industries

Street and Highway Lighting

Food Processing Plants

Agricultural